(Extract)

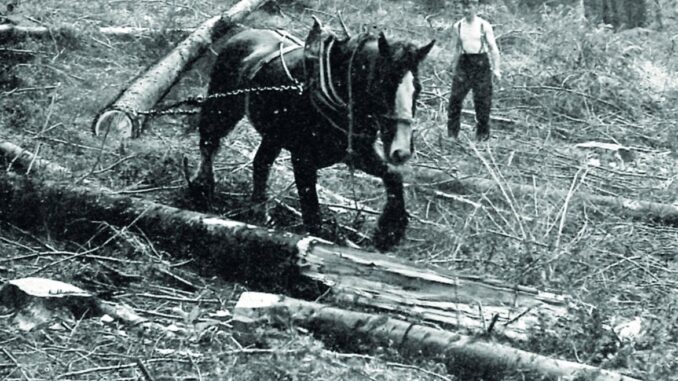

I learned about heavy horses working a harvest season with Geoffrey Morton in East Yorkshire, then learned about timber snigging with Joss Rawlings in Greystoke Forest. We were paid by the ton, piecework, but windblown timber needed special care. Windblow not only causes significant timber losses but it is the most dangerous of all working forestry environments. When windblown trees are uprooted, they lie under severe tension or severe compression, often in a gigantic tangle, like the old game of Spillikins.

One bonus came our way in the form of a job that only a horse could do – taking down hung-up trees in selective thinning. The Commission woodcutters were working in a stand of overgrown Sitka spruce, trying to do a third thinning of trees 35 feet high and six feet apart. They would cut out the ‘gob’ at the base as normal, but when the final felling cut was made, the tree would go nowhere, but just stand there, supported by the dense canopy on either side. These were known as ‘hung-up’ trees, and the usual way to get them down was to use a cant hook, or what is now known as a turning bar. The cant hook is a long wooden shaft, up to 6 feet long for a big one, with a hinged sharp metal hook on an arm at one end. The technique is to place the bar parallel with the ground and dig the sharp hook into the butt of the tree. By pulling or pushing the end of the bar, the tree would be twisted on its vertical axis, and would usually roll off the stump. As it rolled it would lean a little and twist its way through the canopy and onto the ground.

The problem for our woodcutters was that these hung-up trees were so big that, as they twisted off the stump, they would stay vertical and dig in to the wet ground, stuck fast. No amount of cant hook work or brute force heaving could move them. A few trees hung-up like this could be managed by felling the neighbouring trees which were causing the hang up, but in an overgrown plantation almost every tree had the same problem, so taking out the extra trees to make the felling easier would sacrifice better trees that should be left to grow on, and more importantly it would open up wide holes in the canopy and let the wind in. Before long the whole plantation would be windblown.

To harvest them, each cut with the saw must be made with extreme care, after weighing up the stresses, and predicting the effect of the cut on the whole tangled mass. If you get it wrong, a four ton tree can move along the ground at a speed faster than the eye can follow, and serious or fatal injury is a constant hazard.

Even a windblown tree lying flat on the ground can be dangerous. When a windblown tree lies more or less horizontally, the roots rise up out of the ground to form a vertical plate, 8 to 10 feet high, held upright by the weight of its own fallen trunk. When the tree is cut off at the base, the root plate is released and falls back to where it came from. Sometimes it falls back immediately, sometimes it never falls back if the tree has been windblown downhill, and sometimes it stands upright for months and falls back unexpectedly. Whenever it falls, if there is someone underneath the plate at the time, they die. While we were working in Greystoke, a man was killed this way in a Forestry Commission wood in the south country, and we heard about it on the grapevine the same day. The man had been sheltering from the rain behind a cut-off root plate. It had been standing for a few days, but it had been inching back slowly over that time, until it over-balanced and fell.

Windblow represents a major loss to the forest enterprise, and opening the canopy always increases the risk of windblow, so if possible any hung-up trees need to be taken down without felling the trees all around. The hang-ups we had to deal with were third thinnings, too heavy for a man to lift, and because it was selective thinning, the tractor could not get into the wood among the standing trees, so the horses were sent for.

We had to agree a price, and because it was a specialist job, our usual piecework rate per ton was negotiable. Joss asked for 60p a tree. This was not agreed, so he walked away. Next day the boss came to see us to negotiate. Joss was immovable, and 60p a tree was agreed. We walked the horses about a mile to the ‘Berrier end’ of the forest, and followed a four-man cutting gang into the wood. The technique was to wrap a long snigging chain a few times round the butt, just above the cut, while it was still resting on the stock.

As the horse pulled the butt away and off the stock, the whole tree would twist and spin itself out of the canopy as it fell. If it dug into the ground the horse would just keep pulling, and the wrapped chain would spin it out.

We each pulled 100 hung-up trees that day, and it counted as fairly light work for us and the horses. We collected £60.00 each; almost double our theoretical day rate. I asked Joss how he managed to get such a good rate “No problem – he came like a lamb. He had no choice.” Joss knew the price of the cheapest alternative, which was to hire an elaborate portable winch, with operators, and carry it into the wood. Joss priced the job just below the cost of the winch. I was beginning to learn ‘the wrinkles.’

One Horsepower: A long slow walk in the greenwood.

Available here: https://billlloyd.co.uk/one-horsepower/

Paperback: £18.99 plus postage. (1st Edition sold out. 2nd Edition: 10 left.) eBook: £5.00